What should be paid attention to when making bamboo stick incense

Nowadays, when making bamboo stick incense, the following methods should be used first:

1. Traditional handmade fragrance pouring technique.

2. Manual powder coating and mechanical bucket making.

3. Pressure (hydraulic, pneumatic) machine strike.

Using the first and second methods to produce products below four millimeters, the grain production is usually higher than the third method, and the labor intensity is highest in the first method. The bamboo stick fragrance produced by the third method only needs appropriate ingredients, and the resulting product will be more uniform, smooth, and of uniform size. The first and second methods require higher technical requirements from workers. Each factory has its own unique skills in producing bamboo stick incense, but I think the following points should be noted (not necessarily accurate, looking forward to guidance from experts in the industry)

1. Reasonable ingredients should be prepared based on the characteristics of using different adhesive powders. Due to the different gelatinous properties and functions of different adhesive powders, the same adhesive powder may have different origins and batches with different viscosities. Assuming that the same ratio is used, problems may arise at times.

For example, simple adhesion into a ball, rotten head, rotten feet, rotten meat, etc. Making incense does not necessarily mean that the stickiness of the powder is better. The ingredients should be stirred evenly. Although some masters can make each incense taste evenly based on their experience, their grasp is not good enough. This can lead to the melting of the wood powder in the area where it is more, and the adhesion of the powder in the area where it is more, causing the fragrance to appear uneven and uneven, and the finished fragrance cannot be smooth and even.

2. Grasp the base powder well, add meat powder, and cover the flour with the strongest adhesive force of the base powder, followed by meat powder, and cover the flour slightly weaker. Assuming that the adhesive force of the meat powder is stronger than that of the base powder, it will briefly rot and smell. The adhesive force of the cover flour should not be reduced, and the flour should be removed briefly.

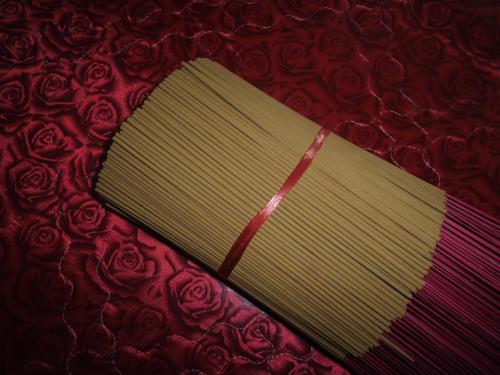

3. The choice of bamboo heart. In traditional bamboo stick making, there is a saying of "one bamboo, two ingredients, and three skills". The best choice is to use bamboo sticks that are evenly sized, without bamboo green or smudged bags. Bamboo sticks with bamboo green are not easy to powder on one side of the bamboo green, have poor adhesion, and are prone to rotting fragrance. The smudged bags are mostly soft and prone to insect infestation.

4. Control of draft: When lowering the water tray, the entire bamboo skewer and incense should be evenly drained. After the water tray is released, it should be inverted vertically to allow the water to flow back evenly before adding flour to prevent large heads, tails, and bellies.

5. Selection of cover flour: Cover flour should have a satisfactory fineness, which makes it smooth and fragrant. If it is used to create color fragrance, light wood powder or bamboo powder should be used to create more beautiful and bright colors. After distribution, it should be sieved.

Article source: Jiangmen bamboo stick fragrance manufacturerhttp://www.dongfangxl.com/

-

09-30

What are the structures of bamboo stick incense?

Bamboo stick incense, also known as string incense, stick incense, or standing incense in Taiwan, and bamboo stick incense in mainland China, is named after its use of bamboo branches, cinnamon bamboo

-

09-30

Incense Manufacturer: Craftsmanship for Making Bamboo Stick Incense

The ancients discovered that any type of spice has the effects of refreshing and calming the mind, so the history of incense burning in China has been over 3000 years, and China can be considered one

-

09-08

Fragrant powder and spice factory: production techniques for bamboo stick fragrance

Nowadays, when making bamboo stick incense, the following methods should be used first:1. Traditional craftsmanship involves hand pouring fragrance.2. Handmade powder coating and mechanical bucket mak

-

08-26

Fragrant powder and spice factory: How to distinguish the quality of bamboo stick fragrance?

We call fragrances made from natural spices "natural fragrances", fragrances with artificially synthesized spices "chemical fragrances", or perhaps "fragrance crafts". Chemical fragrance only has the